3-36kV

Mini subatation

Product parameters:

· Mini Substation

· Combined MV switchgear, transformer, LV transformer

· Rated voltage: 3.3kV, 6kV, 10kV, 11kV, 12.5kV, 13.8kV,

· Rated voltage: 15kV, 17.5kV, 20kV, 22kV, 24kV

· Capacity: 30kVA – 2.5MVA

· Standard: IEC, ANSI, GB

General

UNS-SBT series products is a kind of complete solution which assembles the MV RMU, transformer, LV distribution equipment together according to fixed connection scheme. This series substation is suitable for neighborhood unit, hotel, large-scale work site and high building that the voltage is 1 1 kV 15/22kV/33kV/, the frequency is 50Hz or 60Hz and the capacity is under 2500kvA.

For MV switchgear, we can use AIS (UN-P 28, UN-AM) or GIS (UN-GM6) and SIS (UN-SMS).

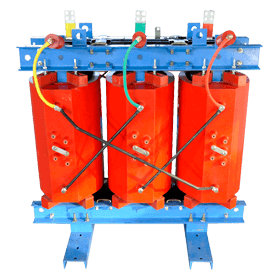

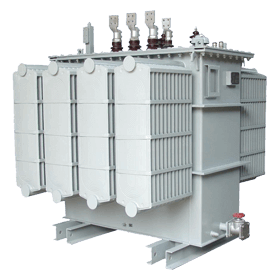

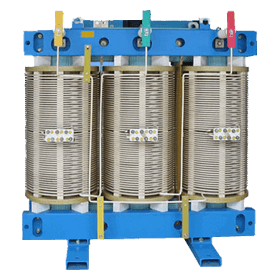

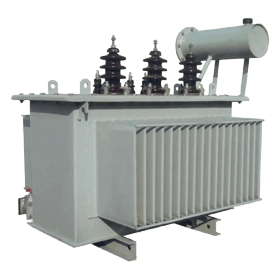

For Transformer, we can use Oil immersed type or Epoxy resin type.

For LV switchgear, we have GGD, or XL, different type of LV switchgear.

Standard

All UNISUN transformers are in conformity with IEC standards, Transformers in conformity with specific country standards can also be supplied. (IEEE, GB)

Name | Unit | HV side | Transformer | LV side |

Rated voltage | kV | 6-40.5kV | 6-40.5kV | 0.4 |

Rated current | A | 630 | 3/75-150/3750 | Less than 4000 |

Frequency | Hz | 50 or 60 | ||

Rated Capacity | kVA | 50-2500 | ||

Pfr withstand voltage | kV | 42/50/70/95 | 2,5 | |

BIL | kV | 75/1 25/1 70/185 | ||

Crust Protection Grade | IP44 | Oil type 55; dry type 65 | IP23 | |

Noisy Grade | dB | 55db | ||

Appearance Dimensions | mm | According to primacy wiring circuit schema | ||

- Products can be customized by customer requirements, above data is standard data, customized data please contact us.

Waiting for your enquiry!

To Learn More info about Us!

Why Buy From Us

Professional Quality Guarantee

Easy and Affordable Payments

Best Product Guarantee

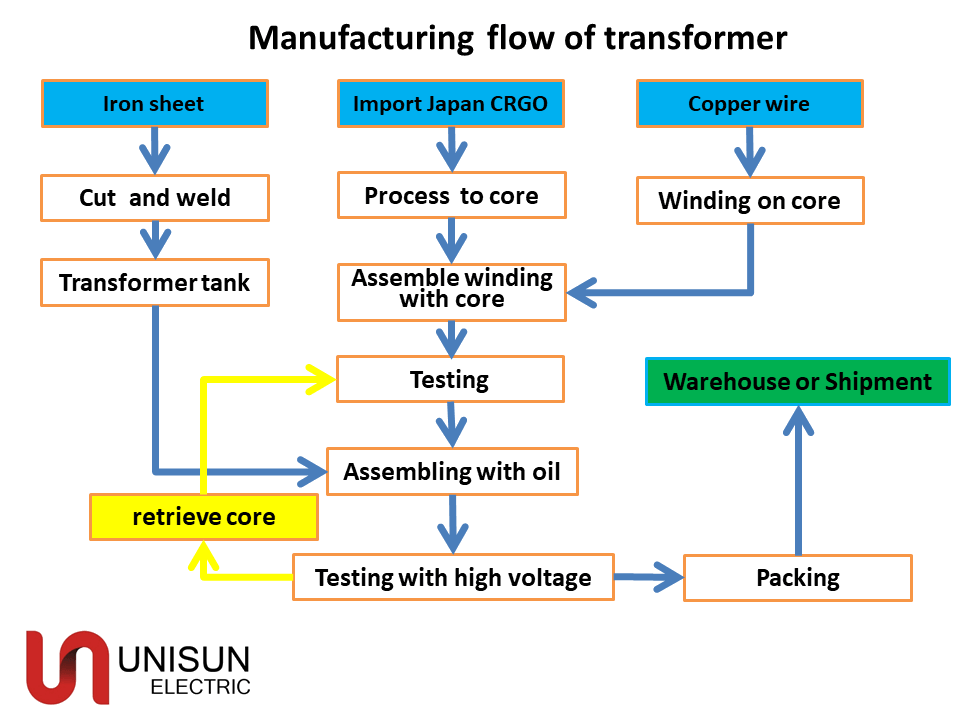

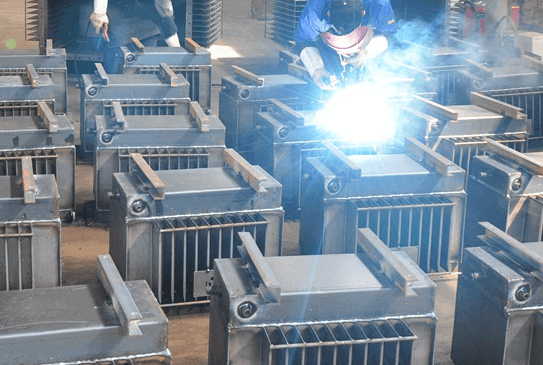

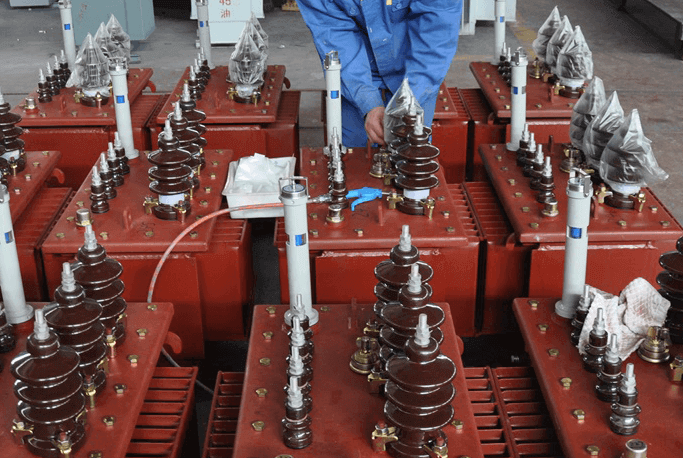

Our Production

The products are designed in strict accordance with IEC or ANSI standards, and the manufacturing steps meet the technological requirements

Primary winding

High electrolytic copper is used as primary winding, High performance insulating paper, combined with silk-wrapped wire, to ensure stable insulation performance, and ensure that the partial discharge tseting data is qualified.

Fine production

Independent production of transformer oil drum, fine processing, strict air pressure test, to ensure that the product does not leak oil.

The products are designed in strict accordance with IEC or ANSI standards, and the manufacturing steps meet the technological requirements

Strict process control

Each step of the process of strict control, packaging product performance test qualified, in line with the standard design requirements.